Tablet Coating Techniques: Boosting Operations in Pharmaceutical Industries

With the general degradation of human health, proper medication ranks amongst the most important requisites today. From minor stomach aches to severe ailments, every individual is always in dire need of proper medication. Now, physician’s prescribed medication is available in a wide range of forms. Some of the most common varieties of medication are the tonics as well as tablets. However, it is important to note that the efficacy and effectiveness of the tablets depend upon their manufacturing and coating. And this is where; the pharmaceutical industries require the Tablet Coating Machine.

For developing an idea on the utility and application of tablet coating machine, it is important to gain profound knowledge of the tablet coating technique and the various other aspects associated with it. Follow the article for some first-hand knowledge of the various tablet coating techniques and how they boost pharmaceutical operations.

Knowing the process

The process of tablet coating can be referred to as the procedure of applying edible paint on the surface of the tablet. As one of the most important step in the tablet production process, this particular technique finds application in the production of almost all kinds of solid dosage form such as pellets, capsules, pills, tablets and drug crystals. Additionally, there are several parameters worth considering, in this particular process. Firstly, uniform distribution of coating must be achieved. And there are quite a few aspects that require attention, in this regard.

Some of the parameters encompassed by the coating technique are the spray patterns, nozzle spacing as well as drop sizes. And the precision in controlling all these parameters will be the key to ensuring a perfect tablet coating process.

The prime objectives

- Before delving deep into the nuances of the coating technique, there is a need of knowing the objective behind it.

- Coating happens to be a camouflage for tablets. It perfectly masks and hides the undesired color, taste or odor of the tablet.

- Perfect tablet coating ensures protection for tablets. And this protection ensures both physical and chemical safety for tablets.

- Other than that, tablet coating happens to be a great way of controlling drug release.

- Moreover, it also strengthens the drug mechanically. Other than that, coating offers the perfect protection for acid-labile drugs from hazardous gastric environments.

Various tablet coating techniques

With these objectives in mind, it is time to delve deep into the various tablet coating techniques. By all means, it will be desirable to have a uniform coating, which will prove to be a major protection against physical stress and pressure. The formation of the coating can take place through single coats as well as multiple layers of coating. Some of the most revered tablet coating techniques are discussed below.

The sugar coating process

Well, this particular process happens to be one of the most primitive techniques of tablet coating. In this process, sugar happens to be the main constituent behind the tablet masking, which further involves several other crucial processes such as sealing, syrup coating, sub-coating, coloring and finally polishing.

Film coating procedure

Of late, this particular process is becoming highly popular and replacing the sugar coating process. By spraying a mixture of plasticizer, polymer, and pigments on rotating tablet beds, this particular process ensures uniform coating.

Organic film coating

Those wishing to coat tablets and pills with the help of the liquid coating technology must place their bets on the organic film coating process.

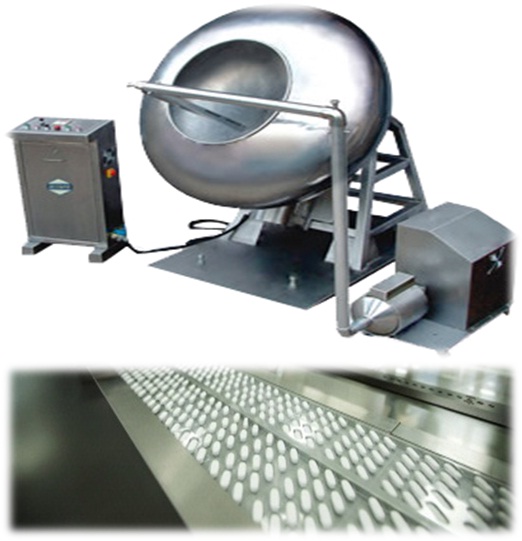

Knowing the equipment

Finally, the entire process of tablet coating and manufacture will be impossible without the help of a few machines. The Octagonal Blender Machine or the Octagonal Blender, the Tray Dryer and the Fluid Bed Dryer are some of the noteworthy machines, in this regard. Other than that, Rotary Tablet Press Machine, Storage Tanks, Jacketed Vessels, Storage Vessels and the Viscous Liquid Filling machine are also of paramount importance.

This article has been written by Arjun Rao, the proprietor of Shree Bhagwati Machtech (India) Pvt Ltd./