All about High Shear Mixer Granulator

High Shear Mixer Granulator is the equipment used during a wet mixing, homogenizing granulating, and drying of powder in a variety of industries like pharmaceuticals, chemicals, cosmetics, food and beverage, and general mixing industries. It offers a controlled and effective channelized process to achieve product homogeneity, fluidity, stability with the mechanism of a lower heat transfer and a clean and hygienic air medium using proven manufacturing expertise.

The parts of a High shear Granulator include-

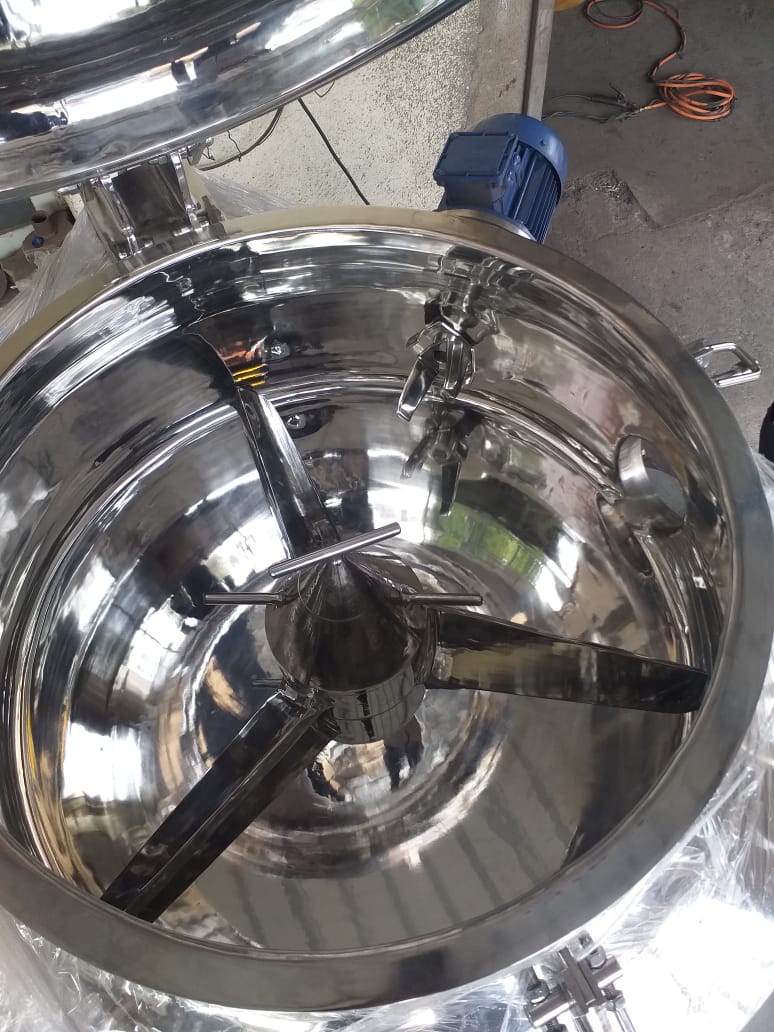

- A cylindrical or a conical cylindrical mixing drum

- An impeller with a trio blade system

- A primary chopper and a supplementary chopper

- Motor and a discharge pot

An impeller is employed in mixing the dry powder and spreading the granulating fluid in high shear granulator normally rotates at different ranging speeds. The chopper forms part of the high shear granulator and is used to break down the wet lump to produce granules. These rapid mixer granulators are categorized into two types which are the vertical axis and horizontal axis and can be operated either continuously or in batches. They are used in pharmaceutical industries due to their capability to manage difficult feed formulations comprising fine cohesive powders and high viscosity binder fluids. A vertical high shear granulator is one in which the impeller shaft rotates in a vertical plane and the impellers are blade-like. It could be a top-driven or bottom-driven unit. In a horizontal high shear granulator, the impeller shaft rotates in the horizontal plane.

Advantages of the High Shear Mixer Granulator

This granulation machine offers a lot of advantages like-

- They need a small quantity of the binder solution for the granulation process and granulation can be achieved within a shorter period.

- The granulation endpoint can be predicted while using a high shear granulator leading to consistency along with short drying times

- Reproducible less friable granules with uniform particle size distribution can be achieved with the help of this superlative high shear mixer granulator.

- The Rapid Mixer Granulator (RMG) minimizes any exposure of drug dust to workers as it reduces dust generation.

- Greater densification and production of less friable granules

The Factors affecting the granulation process of a high shear granulator are-

- The physical properties of the material to be granulated

- The type and quantity of the excipients used

- The type and amount of binder solution used in the process

- The process variables include the load of the granulator bowl, impeller speed, granular design, and the wet massing tire.

The granulation technology is affected by the speed and the high shear granulator manufacturers provide an insight based on different technologies and their applications while purchasing a rapid mixer granulator. All the machine parts also need to be evaluated including the specification demands. A few elements comprise-

- The high-speed mixing as well as granulation

- Fitting Discharge Plug

- The High precision mixing machine

- The Mixing impeller along with the blade angle

Bottom line– The High shear mixer and granulator are designed for an efficient and homogeneous wet granulation of powders to form medium to high-density granules that possess great flow ability and compressibility. This equipment offered by Granulator Manufacturers can be used to mix both dry and wet powders. It is designed in such a manner that each part contributes to its performance, safety, and reliability. The regulations laid by the government from time to time also ensure that they have tight seals to provide safety. They also help in superior removal and easy cleaning.