Description

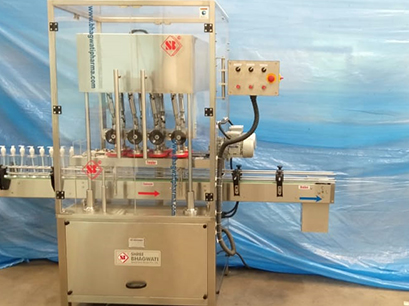

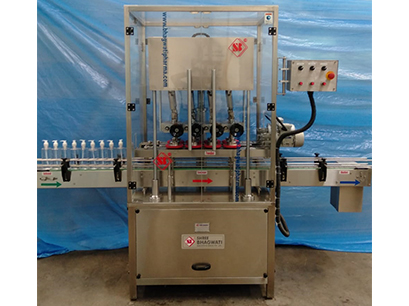

Inline Capping machine Depending on customer output needs, It specially designed for the tightening of pre-threaded caps and consists of a linear capping unit, stainless Steel slat conveyor and gripping belt assembly, The filled bottle coming with cap chute and pick up cap with the cap comes on an in-feed conveyor where the cap is tightened by three/ four roller wheel pairs of rollers while it is being held by the gripping belt. The speed of the slat conveyor and bottle gripping belt is synchronized and can be varied by AC variable inverter drive. The inline capper machine can be provided with the Cap elevator , rotary / vibratory feeding system for automatic cap dispensing , this systems fixed by our production team as per cap and bottle designed.

Inline capper / linear screw capping machine best suitable for Detergents, Oils , Liquid soaps , Household/janitorial cleaners , Glue/Adhesives ,Household cleansers , Herbicides , Polishes , Lube oil, edible oil, Pesticide , cosmetic bottle glass jar or bottle, Jerry can, lubricant can, HDPE jar or bottle, PET jar or bottle Inline / Linear belt gripper type capping machine suitable for Pharmaceuticals, Dairy, Breweries, Edible Oil, Food, Distilleries, pesticides, Toiletries, Cosmetics, Lube, Ancillaries etc.

Specification of the equipment machine’s basics :

PARTICULAR |

SPECIFICATION |

|---|

Model |

SBCS-100S |

Machine Name |

Automatic Linear Screw Caps Sealing Machines |

Option |

With Bowl or With Cap Elevator |

Production Speed Per Hour |

1800 to 3600 Bottles per Hour (Speed Depends up on the size of caps & bottles). |

Capping Unit |

Magnetic Screw Capping Head with Torque Adjustment |

Caps Feeding |

Vibratory Bowl Feeder |

Caps Hammering |

Pneumatic System |

Machine Motion |

Rotary Motion -Index Based |

No Cap in Shute Elevator Stop (If machine is with Elevator) |

Sensor |

Suitable for Products |

PET / Glass/Aluminum/ HDPE Bottle |

Application |

To Tight & Seal the Caps on Bottles |

Up-Down Movement |

Mechanical (Cam System) |

Vibrator Pillar Mounting |

Main Platform |

Speed Synchronization of Star Wheel & Capping Head |

Variable Frequency Drive |

Working Height |

860 mm (+50 mm) |

Conveyor Length |

6 Feet Depending upon the product |

Machine Weight |

Approx 300 Kgs |

Machine Platform |

Approx 1210mm (L) x 810mm (W) |

Machine Dimension |

Approx 1830mm (L) x 1220mm (W) x 2440mm (H) |

Change Parts |

Required in case of change in Cap Size & Bottle Size |

Machine’s material of construction :

Machine main frame |

Square Pipe, Stainless Steel 304 |

Machine Coverings |

Complete in Stainless Steel 304 |

Product Contact Parts |

Stainless Steel 304 |

Non Contact Parts |

Stainless Steel / Mild Steel / Aluminum / Teflon (Whichever is applicable) |

Conveyor Slat |

Stainless Steel 304 Slat with Nylon Strips on Side |

Conveyor Shafts |

Mild Steel with Hard Chrome or Zinc Plating |

Conveyor Sprockets |

Mild Steel or Nylon |

Bearings |

SKF / Nachi / Timken |

Plating(Wherever Applicable) |

ENP / Zinc / Hard Chrome / Blackening |

Capping Unit |

Stainless Steel .304 |

Bowl |

Stainless Steel 304 |

Vibratory Bowl Feeder |

Mild Steel Cladded in Stainless Steel 304 |

Vibrator Stand |

Mild Steel with ENP Plating |

Cap Elevator frame (If machine is with Elevator) |

Stainless Steel 304 |

Elevator Belt |

PVC |

Shute |

Stainless Steel 304 |

Support Rod on Existing point of indexing Starwheel |

Stainless Steel 304 |

Star Wheel with Back Guide |

12 mm thick UHMW / Nylon |

Guide Brackets |

Spectra make – Plastic |

Guide Size |

100mm / 150mm |

Guide Rod |

Stainless Steel 304 (10mm Round Bar) |

Slat Chain Pitch |

3.5” Stainless Steel 304 |

Capping Head Pillar |

Mild Steel with ENP / Hard Chrome |

Machine’s electronics & pneumatics components :

Capping Head Motor Make |

1 H.P Bonfiglioli |

Capping Head Gear Box Make |

Bonfiglioli Ratio: 20:1 |

Cap Elevator Motor Make (If machine is with Elevator) |

Bonfiglioli |

Cap Elevator Gearbox Make (If machine is with Elevator) |

Bonfiglioli Ratio: 20:1 |

Capping Head VFD Make |

1 H.P Delta |

Sensor Make |

Sick / Leuze / Panasonic |

Proxy |

Autonix / Pulset |

“No Cap in Shute Elevator Stop” Sensor (If machine is with Elevator) |

Panasonic |

Electrical Wiring |

Ferrule Numbering on all the wires with Proper Markings |

Electrical Components |

ABB / Delta /Spectra |

Pneumatics |

SMC / Festo / Janatics |

Air Pipes |

SMC / Festo / Janatics |

Wires & Cables |

Labb |

Control Panel |

Relay Card (Push Button Type ) |

Machine’s power & air consumption requirement

Power |

1 H.P / 230 V.AC |

Phase |

Single Phase |

Compressed Air Required |

3 H.P Compressor (6 bar pressure 0.5 CFM) |

Optional accessories (if required by customer at extra cost)

- PLC+HMI

- Flame Proof Control Panel & Motor for Flammable Product

- Polycarbonate Enclosure with Stainless Steel Structure.

- Cap Elevator

- Big jar capping machine will be made bigger so some of above specifications will be changed.

Specification

Specification Features

Features