Automatic Paint Filling and Packing Machine

Paint is a colouring material, which changes its state from liquid to solid after being applied to a surface. It shields the appearance and colour of an object.

The paint filling process is a major stage in the paint manufacturing line. It needs high precision, speed, and labour cost. While deciding the best for paint filling or similar products, one should keep in mind the various models available that can be adjusted and designed according to the explicit requirements of each product and customer. Two technologies can be applied to paint filling machines.

- Volumetric filling- It is used to fill pails and cans. The volumetric filling system controls the filling procedure using a faucet that controls the quantity poured by the dosing unit into the vessel.

- Gravimetric filling-It is used to fill pails, drums, containers, and cans. The filling control is determined by a scale that provides the quantity of product poured into the container.

Industries involved in producing a large number of paints prefer more automation in the filling and packing process.

Working Principle of Paint Filling Machine

Paint filling machines are explicitly designed to precisely discharge the viscous liquid. This machine works upon the principle of a pneumatic system, and its correctness depends on the viscosity of the product.

Piston stroke length controls the quantity of product discharged. After the stroke length is set, each rotation dispenses a uniform quantity of product. When an input is fed, the piston draw-out the product from the reservoir and puts it into the product cylinder. To process output, the product is passed from the product cylinder to the output container.

An incorrect filling can cause a leak and drippage that may cause the elimination and repack of the product. Automatic machinery can provide two key factors needed during the whole process, speed and accuracy. Accuracy is required for regulating the machine and speed for filling and packing lines.

Salient Features of Paint Filling and Packing Machine

- Accuracy is obtained using the filling by weight process.

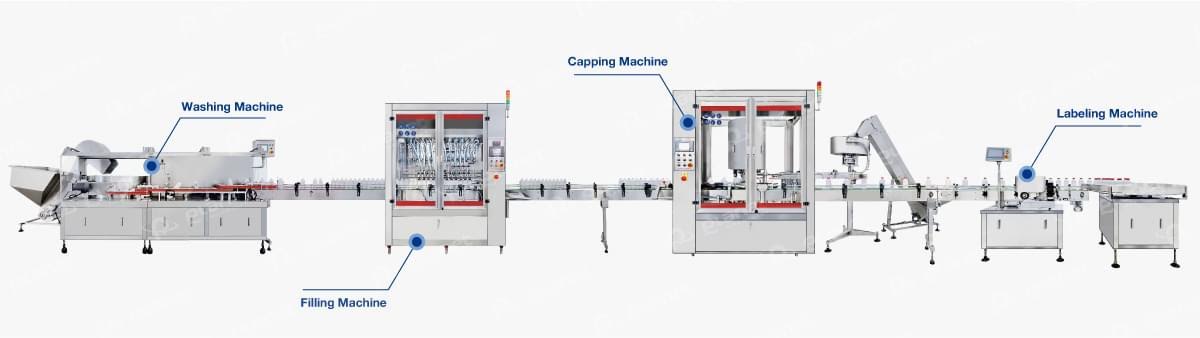

- Labelling and capping machines can be combined into a single block of the unit to avoid complexity.

- Various alternatives are available for capping and lidding of different varieties of containers.

- Pneumatic system components provide suitable blast-proof procedures and maximum security to the machinery.

- Small tanks are used for a steady flow of fluids, despite different viscosity.

- Configuration and controls of the machinery are easy to handle.

- An emergency stop control unit is provided.

- The whole structure and outlets are made up of Stainless steel.

- Has the ability to adjust accuracy and volume precisely.

Different types of product that can be filled with Paint filling machine

- Glues

- Paints

- Inks

- Sealants

- Solvents

- Resins

- Coatings

Depending upon the needs of a manufacturing plant automation of machinery can be increased and decreased. Whatever the size of container, pails, and cans that needs to be filled. These units perform with maximum efficiency. Industries that work with large amounts of production often prefer fully automated machines.