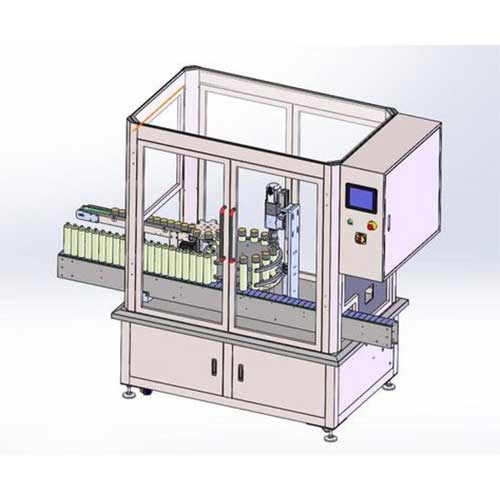

Capper Machine / Bottle Screw Capping Machine for Rotary and Inline Capping systems

The screw capping machine is the packaging equipment used by every major industry that needs to sell its products in any type of bottle form. This machine makes easy the sealing of bottles, vials, and containers. The industries involving the massive use of this machine are FMCG and pharma. Capping is well guarded by a sterile or aseptic environment to ensure that the packaged product is free from any germs. Pharma companies generally opt for automatic capping machine and bottle filling machines side by side in order to ensure the bulk packaging of the bottles.

What is an Inline Capping System?

An Inline Capping machine is customized industrial equipment designed depending on the output needs of the clients. It basically consists of a conveyer belt and comprises a capping unit made up of stainless steel.

Integration of this system with screw capping machine

The inline system can be a linearly designed one. It can be often alternated in use with a rotary system which is generally aligned in a circular fashion. The bottles to be filled is placed in line with cap chute. It picks up the cap kept on an in-feed conveyor that is tightened on the cap by pairs of wheel rollers being tightly held by the gripping belt. It is ensured that there is always a synchronization between the speed of conveyor and bottle gripping belt. This whole configuration is connected to an AC variable inverter drive. An automatic system is provided with the inline capper machine and the rotary feeding system for assuring automatic cap dispensing.

The output rate of the Inline Capping System

An automatic linear screw capping machine has the capacity to give a production rate of 1800 to 3600 bottles per hour. However, the speed can be increased or decreased and it also depends on the size of the cap and bottles. A stainless steel machine having a machine dimension of approximately 1830mm (L) x 1220mm (W) x 2440mm (H) weighing around 300 kgs is perfectly suitable for PET bottles, glass bottles even a few aluminum bottles. The machine is used to tighten and seal these bottles before the final labeling and distribution in the market.

The rotary capping machine, on the other hand, is used to work on medium and high productions with a speed range of 50 to 600 bpm. This machine is extremely versatile and can work on the screw on to snap on bottles, push-pull caps, and even on dispenser bottles.

The Bottom Line

Shree Bhagwati Machtech Pvt. Ltd., headquartered in Ahmedabad, has been pioneering the manufacturing of packaging and labeling machines for industrial purposes. The company has been successful in tapping the domestic as well as the international market for more than a decade. The company has built in technology for new improvisation and customization as per the clients’ requirements and requests. New technological investment, vast infrastructure, and skilled workforce at service guide the success story of this company.