How Does a Fluidized Bed Dryer Work for Drying Applications?

Fluidised Bed Dryer – Effective Drying Systems for Industry

Fluid or fluidised bed dryer is an excellent drying system that can be used for applications like drying of powders, mixing of powders and agglomeration. This is efficiently employed for applications in chemical, pharmaceutical, dyetuff, foodstuff, dairy and various other process industries. Fluid bed dryers are often employed with the spray dryers and granulation systems for effective drying, mixing, granualtion, finishing and cooling of powdered substances. These are often preferred over rotary dryers for drying and cooling a wide range of polymer materials which require precise control of residence time and temperature for effective processing.

Fluid bed Granulator / Fluid bed dryer / Fluid Bed Processor / Glatt Fluid Bed Processor / combo / Multi Purpose available range from 20 kg to 1000 kegs batch size.

Machine General Layout for Fluid bed Coater/ Processor / Multipurpose

Lab Model Fluid Bed Coater / Processor / Fluid bed dryer – 2 kg to 20 kg batch sizes.

Rapid Mixer Granulator / High Speed Mixer and Granulator / High Shear Mixer Granulator

Fluid Bed Coater(Bottom Spray) 60 /120/ 250/ 500 kegs batch size.

High Shear Mixer Granulator with Co Mill , Vacuum powder Transfer systems , Fluid bed processor / Glatt Fluid Bed Processor /coaters.

High Shear Mixer Granulator with Co mill

Working Principle of Fluid Bed Drying System

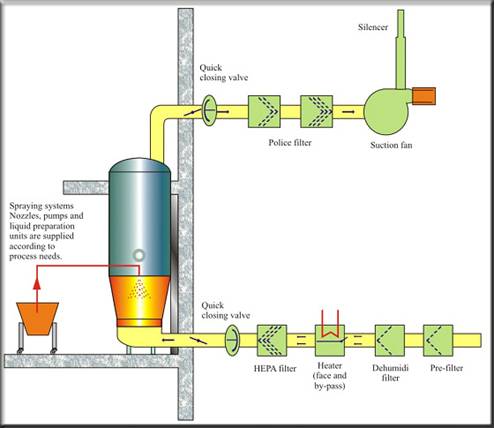

A fluidized bed dryer works on a principle of fluidization of the materials. In the fluidization process, hot air or gas flow is introduced through the bed of solid particulates. This gas or air will move upwards through the spaces between the particles. As the velocity increases, upward drag forces on the particles increase and at a stage become equal to the gravitational forces beneath. Hence the bed is said to be fluidized and the particles are suspended in the fluid.

Automation Process of Fluid Bed Dryer

In a fluid bed dryer used for powder drying, , the air is sucked inside from the surroundings with a fan-run with an electric motor inside the dryer. The air then passes through the heating system within the dryer and gets heated up. This hot drying air is then made to flow through the bed of the moist materials that are laid on the shaking perforated steel bed. This air is introduced with the required velocity and temperature that the bed gets fluidized allowing intimate contact of each particle with the air. As the bed vibrates or shakes, the particles in the bed are carried forward slowly along the length of the dryer. All the moisture present in particles gets sucked by the hot air which then escapes into the dust recovery system and is recycled for further use in the process.

The velocity and temperature of the air can be controlled as the particles pass on the bed and hence very wet to sticky materials can also be dried with a fluidized bed dryer effectively. The dried material is then fed into the cooling zone where cool air reduces the temperature of the material to the required state. The complete process is performed by the automated system that eases the processing.

Therefore in this way product or powder drying can be efficiently achieved with the help of a fluid bed dryer.

There are various advantages of fluid bed dryer in pharmaceutical industries. Some of them are as follows.

Advantages of Fluidized Bed Dryer / Glatt Fluid Bed Processor

- High thermal efficiency is achieved when the thermal energy is supplied by internal heat exchanger

- Low Capital Cost

- Ease of Maintenance and Control

- High Heat and Mass Transfer Rates

Applications of Fluid Bed Dryers in Different Industries

- Food Industries

- For food processing, dehydration & preservation of food

- Fertilizer Industry

- For drying inorganic fertilizers

- Pharmaceutical Industry

- Drying of medical components like capsules, granules, powders

Buying Fluid Bed Dryers for efficient Drying Processes

Those looking to buy fluid bed dryer for drying powders, mixing or agglomeration processes can find some of the best models in required specifications at Bhagwati Machtech. Shree Bhagwati Machtech is a leading machinery supplier in India offering high quality and reliable fluid bed dryers for mixing of dry powders, agglomeration and drying applications. Visit https://www.bhagwatipharma.com to know in detail about the company offering the best fluid bed dryers for industrial processes.

SHREE BHAGWATI fluid bed dryer range is best suitable cGMP, USFDA and CE standard compliant fluid bed dryer / processor / coater and granulation machine designed to uniformly and quick effectively dry powder and granules. our equipment With a multi-function capability available, We offered our fluidized bed dryer with top spray systems for granulating, bottom spray unit for coating and specially spray pelleting or coating systems .

|

MODEL |

FLUID BED DRYER 15 |

FLUID BED DRYER 30 |

FLUID BED DRYER 60 |

FLUID BED DRYER 120 |

FLUID BED DRYER 200 |

FLUID BED DRYER 250 |

FLUID BED DRYER 300 |

|

Container Vol : Litres |

50 |

100 |

220 |

430 |

590 |

780 |

950 |

|

Batch Capacity : Kgs |

15-20 |

30-40 |

60-75 |

120-140 |

200-225 |

250-280 |

300-330 |

|

Heating Load : KW for Electrical Heating |

9 |

18 |

36 |

54 |

Electric Heating Not Recommended |

||

|

Motor H.P. |

3 |

5 |

10 |

15 |

20 |

25 |

30 |

|

Drying Temp oC |

50-80 |

50-80 |

50-80 |

50-80 |

50-80 |

50-80 |

50-80 |

|

Approx. Steam Consumption Kgs/Hr (Steam Pressure 3 Kg/cm2) |

15 |

25 |

50 |

100 |

160 |

200 |

250 |

Higher Model 1500Liter & 2000 Liter please email to us your requirement .

Shree Bhagwati is offers fluid bed machines series : Small Mini Lab model Fluid Bed Dryer, Mini Fluid bed granulation, Lab model Glatt Fluid Bed Processor machine , FBD – Fluid Bed Dryer Granulator and Coater machine, FBG – Fluid Bed Dryer Granulation equipment and cGMP – US-FDA stander FG Fluid-Bed Dryer with PLC touch screen and SCADA base operating systems capacity 10 kg to 1000 kg batch.

This article has been written by Arjun Rao, the proprietor of Shree Bhagwati Machtech (India) Pvt Ltd./