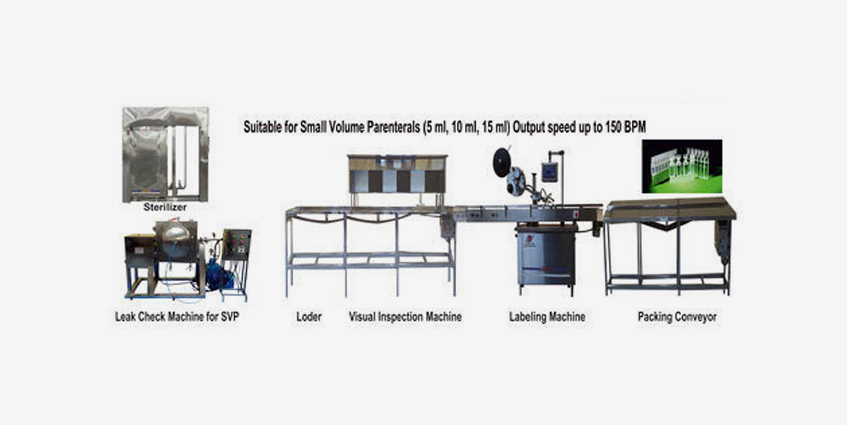

IV Bottle Packing Line

Description

We offer LVP – IV bottle Leak check machine, IV bottle Inspection machine, IV bottle labelling machine, IV bottle Packing conveyor

IV BOTTLE LEAK TESTING MACHINE

IV bottle Leak testing machine pressure testing online thru rotating unit

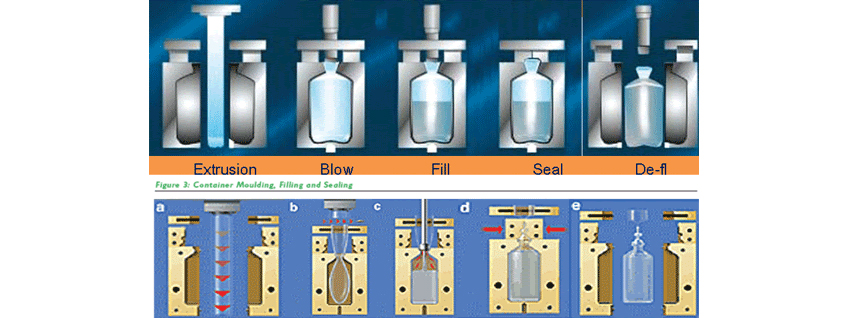

- IV bottle testing any pin holes left out during the forming and the filling in Blow fill seal or FFS bottle pack machines.

- Machine conveyor belt feeding bottle to rotate the flexible Bottles under pressure with mechanical adjustable round bar or strip attachment.

- IV bottle leak machine can be installed just before the Visual inspection – Labelling Machine and conveyor packing line.

- During operations Sometimes changes of having a very minute pin hole which cannot be detected in normal course, but when it passes through the machine under pressure this pin holes is immediately open and given the leak and spraying , that is, how this machine ensures that there is no leakage or pin holes in the bottle.

IV bottle inspection machine , INSPECTION M/C for LVP IV BOTTLE

- Our machine Designed as per cGMP – Current Good Manufacturing Practices compliance.

- Machine structure is made stainless steel AISI 304 with matt finish.

- Bottle visual inspection with high output.

- Black & white board as per GMP norms

- Three way Belt drives through gear motor with variable frequency drive.

- Easy maintenance.

- Rigid Vibration free Construction.

Top Side Labelling Machine, Top Label Applicator Application On Any Product

- This Model is suitable for applying sticker labels on top of any type, shape & size of container.

- Depending upon the size and shape of the bottle or container, the conveying arrangement can be designed such as belt or slat conveyor with pusher depend of bottles.

- Our top labelling machine shall be use Containers like rigid/flexible IV bottles, boxes, jar lids, cassettes, books & diaries, corrugated boxes, blisters ect. can be labelled on this machine operates at the speed of 100-200-300 containers/min. (depending upon feeding arrangement) Configuration of the machine can be designed as per specific requirement such as folding the lable on2/3 sides etc.

The same top side labellers model is used for FFS Ampoule cassettes for Top & Bottom labelling with special configuration.

PACKING CONVEYOR BELT.

- Packing conveying of goods for packing.

- PVC and endless belt for long life.

- Structure is made from AISI 304 with matt finish.

- Belt-alignment system for long life & striate running of belt.

- Available in varioue sizes : 9″ Or 12″ width and any length.

- Food grade PVC coated Widely used in any packing lines in foods, Pharmaceuticals, Cosmetics, Distilleries & Breweries, Pesticide etc.

ROLLER CONVEYORS

- Our designed in straight or turning type with desired slope or specifications.

- Rollers of M.S.Nylon / S.S. of diff. dia. & pitch are available

- It can be free moving or with positive drive.

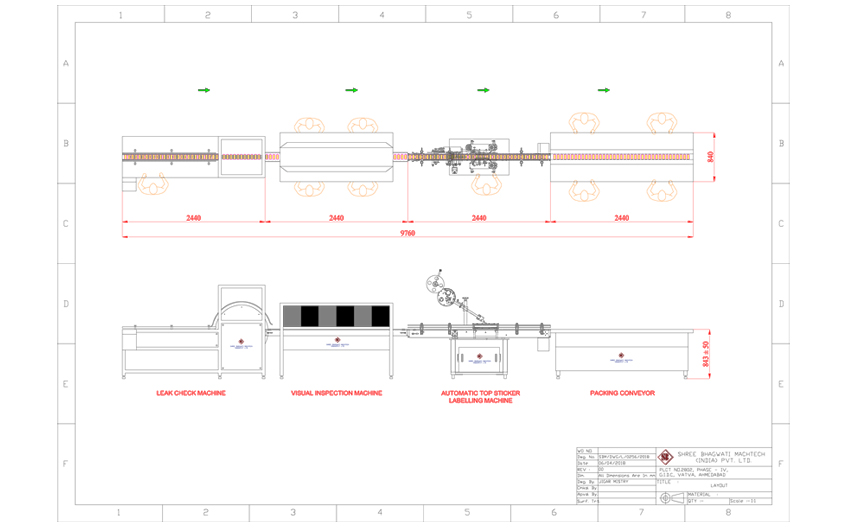

General Layout:

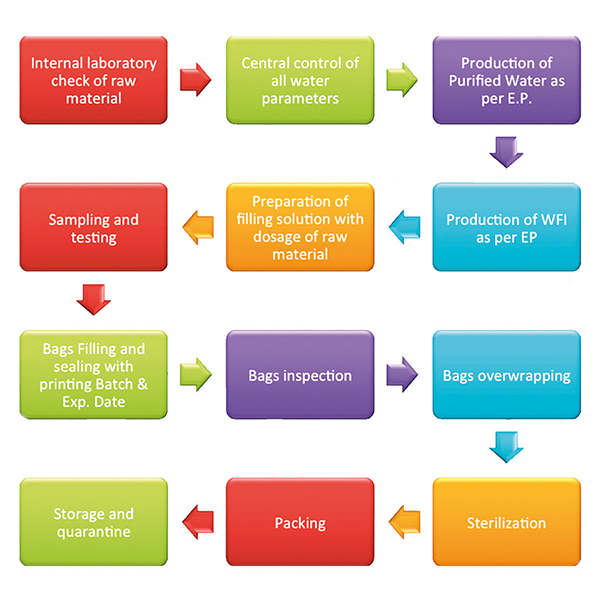

We designed equipment for IV bottle Packing line for small or mid as well Multinational pharmaceutical brands and we offer in WFI, IV Fluids, LVP, SVP production line equipment with maximum parameters for best useful to our customers.

IV bottle Manufacturing with Blow fill fill seal machine, IV bottle making machine

Small Volume Parenteral IV vial solutions (or SVI – Small Volume Injection) IV injection that is packaged in vial or containers labelled as containing not more than 100 ml with class of SVP/SVI , all the sterile products packaged in vials, ampoules, cartridge, syringes, bottles (or any other container up to 100 ml or less volume).