Net Weigh Filling Machine – Net Weigh Fillers, Weighmetric Filling Machine

Description

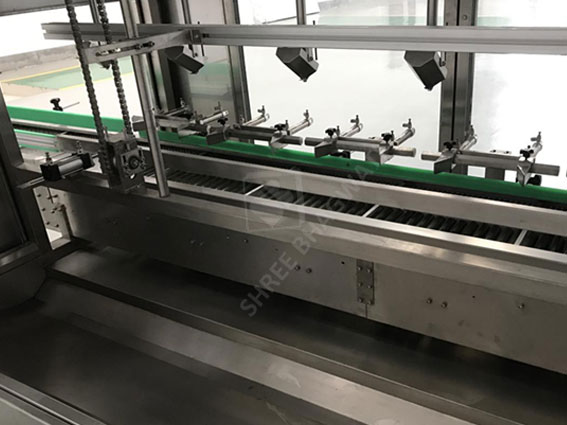

Shree Bhagwati is one of the leading manufacturer, supplier & Exporter of Net Weigh Filling Machine – Net Weigh Fillers , Weighmetric Filling Machine suitable for Premium Water, Edible oil, Mustard oil, Lube / lubricant oil, solvents, bulk alcohol, specialty chemicals, color paint, inks, corrosive chemicals and bleach to initial weigh the product to be filled prior to it’s dispense to the container in direct to make sure total precision of fill level in each container. This not only way you’ll have aesthetically agreeable fill-line grades, but also that you will have steadiness from one container to the subsequently. Achieve such precision also means you won’t be below or excess numbers of containers, which can accumulate the funds in product and boost the consumer contentment levels.

Net weigh filling machine the fills the material of the product with a net weigh. It is used for filling wide array of regular and irregular sized products. There are special trays where the container moves towards the filler, gets filled and moves on. This net weigh filler machines is advantageous to different industries and has reduced the manpower.

Features & Benefits

Accurate weight of the quantity for perfect and constant fill. Moderate fill arrangement prevents defeat of quantity through overspray.

Compatibility

Automatic Net weight filling is well-matched with an extensive variety of commodities and can be used for a section of an ounce up to five gallons value of produce.

Advantages:

1.Control arrangement would be Mitsubishi PLC control system

2. Function interface having two rows of the color function interface, suitable process, steady and consistent.

3. Function development for feeding nozzle is prepared with filling blocker. This mechanism can understand diving filling according to the substance property.

4. Filling illustrate is the filling result displayed in the unit of mass, instinctive and clean

5.Real time alarm could alarm automatically when the error happens, mechanical stopping and alarming when the arrangement appears serious breakdown.

5. Electrical essentials would be adopting the global well-known brand to make certain the extraordinary value, constancy and high accuracy.

Machine rudiments of parts contacted with the substance use the 316 premium SS and non-poisonous, rust free PTEF hose. Further machine parts used by 316 high quality SS material.

6. Expansion purpose could carry out the particular arrangement according to the consumer’s necessities.

7. Counting exposure would real time count, reflecting the output directly

8.Filling detection could help if No-bottle no-filling, it would stop the filling if bottles are not enough.

9. Function improvement would designed by smart weighing feedback arrangement to understand the unmanned debugging purpose.

10. Environmental defense arrangement would Equipped with ecological frame, realize more dirt free and hygienic process environment

11. Maintenance state would fully accord to the GMP standard model, easy to disassemble and dirt free.

12. Filling dose is more precise, the unique ± 1% of filling accurateness increased about 10 times

Net Weigh Filling Machine – Net Weigh Fillers , Weighmetric Filling Machine Suitable for HDPE bottles / jar , Jerry can and Metal Tin:

Features

Features Specification

Specification