Pharmaceutical Turnkey Project Consultant – Shree Bhagwati Machtech

For the past 10 years there have been rapid changes in the manufacturing industry and mainly contributed technological advances. Most pharmaceutical industries have “trimmed the fat” and are concentrating on ways to increase production efficiency while reducing their cost of operation. There have been rapid discoveries in chemical ingredients requiring new production systems and unique technologies that have required qualified and experienced personnel and consultants to help businesses adopt the new discoveries.

While in the past consultants in industries were important in driving cost reductions, mergers and acquisitions, nowadays they are also important in dealing with the massive challenges facing the industry. When these challenges have been fully addressed there is guaranteed attainment of efficiency and productivity.

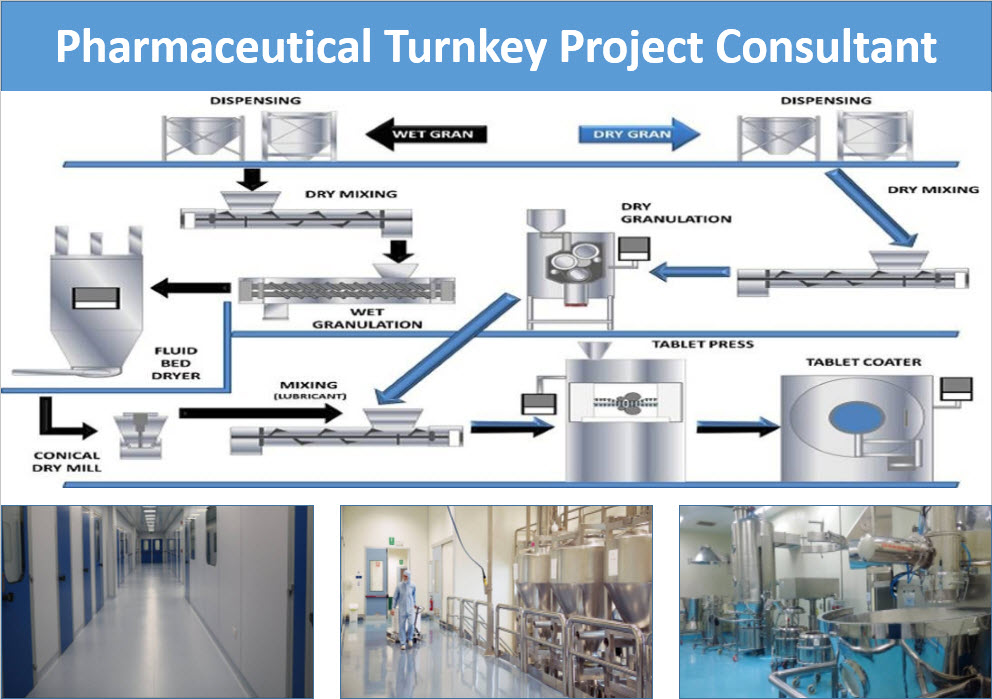

Pharmaceutical manufacturing involves large amounts of raw material going through several processes in a batch operation and a flow process. This process also involves packaging an active ingredient into a tablet or other form in the most efficient process.

Role of Consultants in Any Pharmaceutical Industry

To achieve this level of efficiency, consultants have been able to help pharmaceutical manufacturers become more competitive and successful in today’s market. The development of supporting turnkey project consultants for IV fluids, injectables, tablets, capsules and many other formulations has been a major contributor to streamlining efficiency in various industries. Gone are the challenges of unpredictable product pipelines after the introduction of the services of turnkey project consultants. Shree Bhagwati Pharma is involved in offering pharmaceutical project consultancies for turn key projects that are in line with international standards such as the WHO – GMP, USFDA, MHRA, TGA and cGMP rules and regulations. These leads to flexibility and cost effectiveness, while at the same time meeting the required regulatory requirements. Some of the specialties include;

- Manufacturing of sterile products; this involves provision of equipments such as the ampoule and vial lines suitable for efficient manufacturing, laboratory as well as research and design where development of new products is required.

- Non- sterile products production; this includes development of equipments for production of tablets, capsules, liquid oral syrups, Ointments and creams which are commonly used in delivery of medications in the pharmaceutical industry.

- Specialized formulations; through continued research, the company has developed systems that maximize yields while preventing expensive product losses and reduced cycle times.

- Process Integration; Bhagwati Pharma offers an entire range of process equipments with system integration in focus. This modular approach enables customers to select specific process modules to suit their manufacturing needs.

Advisory Services In the design phase of the pharmaceutical processes, the company is able to offer complete solutions for setting up and implementing layout designs with detailed engineering, determination of capacities, developing engineering specifications, HVAC system designs, equipment supply, installation and commissioning of projects as the customer may require.

The company has a team of expert auditors tasked with conducting system audits both nationally and internationally. The team also develops proposals and suggestions where improvement is required. This team also develops the required documentation for efficient operation and implementation of quality management systems.

Our architectural team provides services exclusively to the industrial sector, utilizing International codes and standards. We have partnered with our clients from the concept phase through the detailed design and construction drawing phases.

- Projects

- Automobiles

- Ceramics

- Dyes & Chemicals

- Electronics

- Engineering

- Foods

- Mines

- Pharmaceuticals

- Plastic

- Printing & Packaging

- Textile

- Warehousing

- Concept design

- Schematic design

- Design development

- Construction documentation

- Approval/permit drawings

- As-built drawings

- Furniture layouts

- Architectural Imageries in both 2D and 3D for visualization

- Building Information Modelling (BIM)

- Evaluation and selection of primary structural systems

- Preliminary foundation layout

- Preliminary analysis, establishing critical member sizes for preliminary elements

- Primary framing drawings, with sizes of primary members only and indicative structural connection types

- Preliminary assessment of floor vibration and building movement

- Identify high risk / cost elements in structure

- Preliminary input to Architect on architectural elements

- Value Engineering

- Design basis and detailed structural analysis

- Final Design of all primary and secondary structural elements

- Drawings defining all structural elements, including plans, elevations, sections and details with adequate cross-referencing

- Drawings of secondary framing members (stairs, canopies, platforms, walls, etc.)

- Design of connection details or specifying connection forces

- Construction sequences and positions of control / construction joints

- Reinforcing details and bill of materials (if required)

We specialize in providing design, engineering and drafting services for large scale industrial, commercial, residential and retail projects in the field of heating, ventilation and air conditioning systems.

- Design basis requirement

- Heat Load Calculation

- Sizing & Selection of HVAC Equipment (Boiler, Pump, Chiller, AHU, etc.)

- Zoning and Pressurization Diagram

- Air flow diagrams

- Heating, Cooling & Ventilation Schematics

- Control schematics

- Energy efficiency analysis

- Equipment general arrangement plan (AHU, Chiller, CT, Pumps, etc.)

- Ducting plan, section and details

- Acoustic Calculations, Selection of Attenuators and Vibration Pads

- Plant room layout including detailed sections

- Reflected ceiling plans

- Equipment schedules

- Duct fabrication Drawing

- Bill of Quantity

- Design Basis requirements

- Electrical Load calculations

- Lighting layout

- Lighting calculations

- Cable, MCC sizing calculation

- Electrical Single Line Diagram

- Single line diagram-for fire detection and alarm system and gas-based system

- Lightning protection calculation

- Lightning protection layout

- Building management system

- Small power distribution layout

- Power distribution layout

- Security systems layout

- Fire Detector Spacing Calculations

- Fire Detector and Alarm Layout