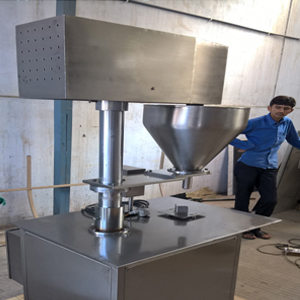

Automatic Double Head Auger Type Powder Filling Machine SBAF-80

₹1,380,000

Operation:

The incoming dry bottle/Bottle sterilized is fed through the in feed Turn Table with suitably guided on the moving Delran flat conveyor belt at the required speed for feeding. There are two separate filling head mounted on machine top plate in the same line. When bottle reaches to the first filling station, it will be held by the pneumatic bottle holder. Immediately it will be sensed by the bottle sensor as soon as it gets signals from sensor magnetic clutch starts to rotate which is mounted on auger shaft. It will fill the desired amount of powder to the bottle through auger, where rotation time is previously saved in PLC control. After filling of first bottle pneumatic piston goes back and release the first bottle to move on conveyor, by the same time second bottle also moves along with the first bottle in empty condition. In second filling head same operation will be performed but this time second bottle get filled and first bottle moves further for next operation. The main advantage of this machine is Pneumatic bottle holding system is directly connected with Auger rotation, so till bottle get filled with powder as per set value pneumatic system will not going to release the bottle.

| Model | SBAF-80 |

| Direction | Left To Right. |

| Output | 20-50 Bottles per minute - Depend on fill size |

| Fill Capacity | 10gm-1000gm –with help of change parts |

| Powder Accuracy | ± 2% |

| No. of Heads | Double |

| Electrical Supply | 2.00 HP For Main Drive. 0.25 HP for conveyor |

| Power Requirement | 230 Volts, 50 Hz. |

| Height of Conveyor | Adjustable from 800 To 850 MM |

| Pneumatic Air | Filtered, oil free, sterile low pressure AIR at 5kg/cm2 |

( 0 Items)

( 0 Items)