Description

We design, manufacture and supply the complete customized automated Sterile and Non-Sterile Ointment/Cream Plant for Lotion/Cream , Delicacies , Hair Cosmetics Products , Skin Cosmetics , Gels , Emulsions , Lotions , Tooth Paste as per the latest cGMP norms with Qualification Documents.

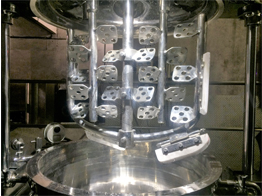

Lotion/Cream , Delicacies , Hair Cosmetics Products , Skin Cosmetics , Gels , Emulsions , Lotions , Tooth Paste , Cream / Ointment manufacturing plant considering Oil Phase Jacketed & Agitated Vessels, Water Phase Jacketed & Agitated Vessels, Manufacturing Vessels with special high viscosity, intimate mixing agitator and in-built or external Micro-Homogenizer having Auto Lifting top lid device & Heating cooling facility, mixing under vacuum condition and Storage Vessels with or without Agitators.

The ointment cream Manufacturing processing plant / HOMOGENIZING EMULSIFIER cosmetics industry machinery and equipment Manufacturer producer is the machineries used for the manufacturing of different kind of products such as gel, shampoo, toothpastes, creams, and lotion and pharmaceutical ointment and creams . This semi-solid emulsion manufacturing plant works by mixing the ointment and water in a homogenous quantity before passing it through the production process.

Specifications Of Cream / Ointment Manufacutring Plant

- Sanitary standard Design

- Internal surface Mirror polished to less than 0.5 Micron RA

- Double Speed contra-mixing slow agitator with step less speed control

- Inbuilt/Inline High speed Homogenizer

- Hydro Lift top covers

- SS 316L contact parts & SS 304 Non-contact parts

- High standard Automation System

- Qualification Documentation like DQ, FAT & Protocols of IQ & OQ

- Smooth processing with low shear force

- Teflon scrapping mechanism with Agitator

- Internal/External re-circulation system

- 100L to 15000L with viscosities up to 1,00,000 cPs

Ointment manufacturing equipment, We normally provide following quality dossier along with equipment – On request (Optional )

- Final design specifications.

- Design Qualifications documents.

- BAR chart and QAP for approval.

- Detailed general arrangement drawing for approval.

- Electrical wiring diagram with power and control circuit, for approval.

- Design calculation and details for all pressure parts, approved by related certification authority.

- Material test certificates for all wetted parts.

- Material track Record.

- Bought out certificates with related code conformity certificates from the supplier.

- Radiography, DP test and stage inspection report, as per approved QAP.

- Final hydro test, running trial report along with visual and dimensional report w.r.t the approved drawing.

- Final as built drawing

- Final conformation certificate of applicable code, by authorised inspection agency.

- Final electrical drawing with power and control circuit drawing.

- FAT protocol and validation document like IQ/OQ/PQ/SAT etc…

- Transfer of products from storage vessel to filling line

- Load Cells for Manufacturing Vessel for weight automations

- Vacuum Transfer Systems for Oil & Water Phase

- PLC based Automation system suitable for SCADA connectivity

- Dedicated Skid, CIP & Sanitization System

- Inter-connecting aseptic piping and valves system

- SS Operating Platform

- SS Control Panel

- Flame-proof System on request

- “CE” marked Equipments are offered with Third Party Inspection & All Electrical Control with ERTL Approval & Test

- cGMP, USFDA compliance, CE certifications, ASME certification on request.

Cream Manufacturing plant Process of cleaning, dispersing, emulsifying, homogenizing, vacuum, heating and cooling in one unit, we offer different product plant as below :

- Cream Manufacturing plant

- Gel Manufacturing plant

- Lotion Manufacturing plant

- Emulsion Manufacturing plant

- Ointment Manufacturing plant

- Shampoo Manufacturing plant

- Conditioner Manufacturing plant

- Hand Washes Manufacturing plant

- Hair Cosmetics Products Manufacturing plant

Plant consist the following equipments and accessories.

- Ointment Manufacturing Vessel

- Wax Phase Vessel

- Water Phase Vessel

- Storage Vessel

- Vacuum Pump

- Control Panel

- Product Piping

- Working Platform

Apllication

- Lotion/Cream

- Delicacies

- Hair Cosmetics Products

- Skin Cosmetics

- Gels

- Emulsions

- Lotions

- Tooth Paste

- Jams

- Dressings

OUR HOMOGENIZING EMULSIFIER , Vacuum Homogenizing Emulsifying Mixer & vacuum emulsifying mixer and making plant , Shree Bhagwati expertise and experience for mixing and blending technologies for cosmetics industry machinery and equipment Manufacturer producer specially for Pharmaceutical Ointments and Creams, Cosmetic Mascara, Lipstick, Shaving creams, gels, Oil emulsion Pigmented creams, gel etc .

Specification

Specification Features

Features