Stainless Steel Jacketed Tank, Master Plant Mixing System

Bhagwati Pharma is one of the most experienced storage vessel fabricator for biopharmaceutical and pharmaceutical industries in India. Our storage containers accurately maintain the temperature of the material inside it. Our skilled professionals are dedicated for building and finishing stainless steel mixing tank. We have wide range of SS containers in both Jacket and Plain form. Our jacket stainless steel mixer maintains the heating and cooling of material in it.There are various methods for mixing with the product be available for different industries. Bhagwati Pharma offers with jacketed mixing vessel tank that also helps to maintain the material used in the industry. In simple terms it can be explained as this type of mixing vessel tank is just like a thermos. One layer in the jacketed tank is been used to regulate the temperature of the contents within the mixing vessel tank. Jacketed Stainless Steel Mixing Tank is been designed in a way such that it can keep the content hot or cold through its jacket enclosure. This type of mixing vessel tank or stainless steel tank is generally been used in industries like bath products, food industries use this in order to temper chocolate and sugary confections. Bhagwati Pharma offers you with Jacketed Stainless Steel Tank as well as Stainless Steel Mixing Tank with different ranges. Following shows some of the applications with the mixing vessel tank.

Bhagwati Pharma provides high quality stainless steel tank for heating and cooling with accurate result at very affordable price.

- Chemical Industry:

- Cleaning agents

- Polishing agents

- Lubricants

- Colors

- Lacquers

- Anti-corrosion products>

- Wax emulsions

- Silicone emulsions

- TiO2-suspensions

- Colloidal suspensions

- Impregnating agents

- Pesticides

- Fungicides

- Pharmaceuticals:

- Ointments

- Gels

- Cough syrups

- Infusion solutions

- Suppository masses

- Coatings

- Lotions (W/O or O/W)

- Paraffin emulsions

- Lipid emulsions

- Disintegration of

- vegetable substances

- Antiseptics

- Serums

- Vaccines

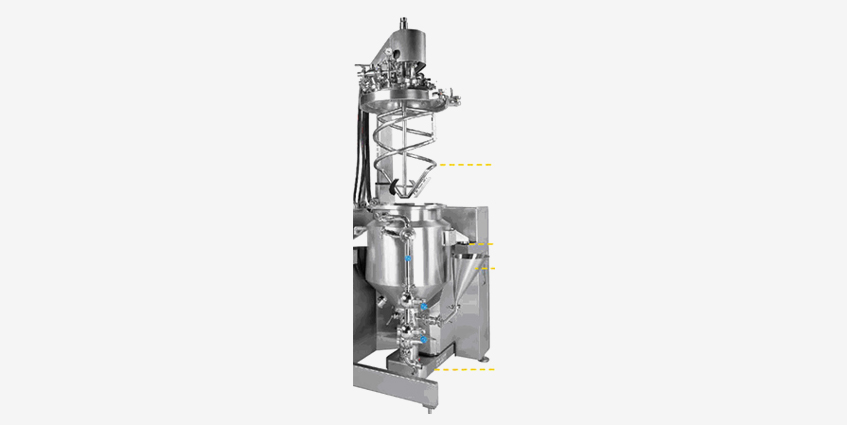

1st stage

- Special pumping rotor for turbulence in the vessel

- high circulation capacity for viscosities up to 100.000 cp

- high pressure for CIP-cleaning gentle circulation

Our Wide Range of Stainless Steel Mixing Tanks and Manufactuirng Plant

- Liquid Syrup Manufacturing Plant

- Automatic Liquid Syrup Manufacturing plant

- Ointment Manufacturing Plant

- Ointment Cream Manufacturing Plant

- Automatic Ointment Manufacturing Plant

- Jacketed Mixing Tank

- Stainless Steel Liquid Mixing Tank

- Automatic Syrup Manufacturing Plant

- Liquid Oral Manufacturing Plant

- Automatic Liquid oral Manufacturing Plant

- Liquid Oral Plant

- Liquid Manufacturing Plants

- Liquid Processing Plant

- Liquid Processing Plant For Pharmaceutical Industry

- Pharmaceutical Liquid Processing Unit

- Liquid Sugar Manufacturing Plant

- Sugar Syrup Manufacturing Plant

- Liquid Oral Processing Unit

- Processing Unit

- Cosmetic Mixing Vessel

- Jacketed Mixing Vessel

- SS Vessel

- Jacketed Reactor

- Jacketed Vessel

- Perfume Manufacturing Vessel

- Mixing Vessel

- Cosmetic Mixing Vessel for Pharmaceutical Industry

- Stainless Steel Vessel

- Automatic Lotion Manufacturing Plant

- Automatic Ointment cream manufacturing Plant

- Cosmetic Cream Manufacturing Plant

- Lotion Manufacturing Plant

- Pharmaceuticals Ointment Manufacturing Plant

- Oral Liquid Manufacturing Plant

- Automatic Oral Liquids Manufacturing Plant

- Sugar Melting Vessel

- Sugar Melting Tank

- Sugar Melting Tank for Pharmaceutical Industry

- Cosmetic Manufacturing Plant

- Cosmetic Manufacturing Plant For Pharmaceuticals Industry

- Ointment Mixers For Pharmaceutical Industry

- Ointment Mixer

- Ointment Cream Mixer

- Ointment Manufacturing Vessel

- Ointment Manufacturing Tank

- Ointment Making Plant

- Automatic Ointment Making Plant

- Jacketed Tank

- Stainless Steel Storage Tank

- Cream Manufacturing Plant

- Cream Manufacturing Vessel

- Automatic Liquid Oral Plant

- Automatic Liquid Oral Processing Plant

- Automatic Liquid Oral Suspension Manufacturing Plant

- Automatic Liquid Syrup Processing Plant

- Automatic Liquid Syrup Production Line

- Automatic Oral Liquid Syrup Manufacturing Plant

- Automatic Suspension Syrup Manufacturing Plant

- GMP Liquid Syrup Manufacturing Plant

- Liquid Oral Processing Plant

- Liquid Syrup Processing Plant

- Liquid Syrup Production Line

- Suspension Syrup Manufacturing Plant

- Suspension Syrup Production Plant

- Automatic Cosmetic Cream Manufacturing Plant

- Automatic Cream Manufacturing Plant

- Automatic Lotion Manufacturing Plant

2nd stage

Dispersing with an optimum generator for finest droplet sizes for emulsions with long term stability suction of powders or liquids directly into the dispersing zone without additional vacuum pump.

Excellent and constant mixing of the vessel content is guaranteed by a special spiral agitator.

Optimum mixing in vertical and horizontal direction.reversible direction of rotation flexible scrapers made of Teflon, free of dead spots can be heated or cooled, thus caring for short heating/cooling times.

The procedure of the mixing process is controlled by means of a modern electric control with touch screen monitor, which can be extended on demand

| APPLICATION |

For Blending, Heating & Cooling |

| CONSTRUCTION |

Vertical, Cylindrical, Top & Bottom Dished End Jacketed, Insulation, Agitation, Leg Supports |

| CAPACITY |

From 100 Liters To 10000 Liters |

| MOC |

Contact Parts S.S.316, S,S,3161 Jacket, M.S., S,S, 304 |

| FINISH |

220 Grit lnside & 150 Grit Outside |

| DESIGN |

Internal, Atm, External: 3 Bar @ 150° |

| AGITATOR |

Propeller, 6 Bladed Turbine, Off Center With Single Baffle Or Nil |

| RPM & SEAL |

500, 750, 1440, Stuffing Box Or Mech. Seal with Cooling Pot |

| SPEClAL FEATURE |

Low Power Consumption No Coupling Inside Or Outside Top Cover welded Or Bolted with |

| ACCESSORIES |

Spray Ball Thermowell with Dial Gauge Safety valve Pressure Gauge On Steam Inlet Connection Level Indicator |

3rd stage

- The combination of special designed high speed emulsifying head and low speed blade agitator with attached scrapers allows to achieve a high efficiency of mixing & homogenizing process.

- The mixture is sucked through the narrow gap between the high speed rotating rotor and fixed stator of emulsifying head. Due to the turbine effect of emulsifying head, the circulation of product in the mixing vessel is formed.

- Low speed blade agitator helps to produce the laminar and turbulent flows in the product and provides the heat-exchange. The teflon (or silicon rubber) scrapers, which are fixed at the outer mixing frame of blade agitator, scrape off the material sticked to the inner wall of vessel.

- Due to the high speed rotation of emulsifying head in combination with the effect of low speed blade agitator and scrapper rotating in different direction (forward and backward),, the mixture is processed by micro-grinding, smashing and dispersing of raw materials and the product can be homogenized completely without any ‘dead’ corners in the mixing vessel. The various types of emulsifying head can be chosen depending on the different feature of products and requirements of customer.

Features

Features