Liquid Filling Machine, Viscous Liquid Filler Machines for Bottles and Vials

At Shree Bhagwati Machtech (India) Pvt. Ltd, we provide high-quality filling machinery for a variety of filling processes. Our product portfolio comprises viscous fluid filling machines as well as those used to fill bottles and vials.

Liquid Filling Machine is a device that has been used in several industries to load raw materials into containers and pack them to create a final product. Different packaging companies have benefited from this machine. In liquid filler, the tanks, container, or vessel travels in a cycle, is loaded by the machine, and is then prepared for packaging.

A liquid filling machinery is one that fills raw fluid materials into containers and ampoules before transforming them into a finished packaging which can be seen on the shelves and purchased. There are several liquid filling machines worthy of mention.

Injectable Liquid vial filling machine – This is widely used to fill vials with medications. It operates on the volumetric concept, using diving nozzles and a pneumatic mechanism with rubber stoppers on top of the containers. The injectable liquid vial system features a stainless steel flat conveyor belt that the vials travel to and move on. The vials are then transported to the filling station, which has 2 to 12 heads. Following the precise filling, the following station places a closure on the head. The basic components of the vial filling machine are a conveyor belt on which the bottles are transported and a filling and stoppering machine on which the vials are loaded and rubber stoppered so that no medical material is wasted and precision is preserved.

Prefilled syringe filling machine– This machinery is best suited for usage in the pharmaceutical industry since it is used to fill a prefilled syringe. A stainless hopper is used to hold syringes. On top of the structure is a pre-filled syringe slot. Piece by piece, syringes are transported to the filling station, where an automated pump is installed. The syringes go to an out feed plate of the syringe filling equipment once they have been injected to the correct quantity.

Liquid bottle filling machine– Bottles are filled with a variety of viscous liquids, like as oil, which is utilized for both food and industrial properties. The volumetric or gravimetric method can be used to fill containers. To fill the bottles, there is a funnel alternative. To impart force to denser fluids, pumps or pistons can be utilized if the liquid is thick or viscous. The liquid bottle filling machine is even used to fill lotions and creams. Swift nozzles enable a quicker and more efficient discharge.

Linear Liquid filling machine – The linear liquid filling machine works on a volumetric basis and can fill up to 1000 ml bottles. The diving nozzle features a suck back configuration and is used to prevent foam.

Oil filling machines – Automatic liquid filling devices, particularly fast-moving ones, frequently perform several advances. Oil filler equipment is one such machine, and it uses the same line to line outward and inward filling ideas. For bulk manufacturing and packaging, the oil can be put in containers, bottles, and jars. The automated 8 head twin-track liquid filled with rubber stoppering machinery is a high-speed, high-efficiency liquid filler with sturdy construction. Automated Rotary Piston Filling and Capping Machinery is also a great option, having a rotary valve for drip-free filling. An AC frequency control system may likewise be used to regulate the pace of such a rotary. Other equipment in high demand are the Engine Oil Filler, Volumetric Oil Filling Machine for Lube and Oils utilized for gastronomic and medicinal purposes.

A liquid filling machine typically has the following features:

- Volumetric or Gravimetric Filling: Liquid filling machines can use either volumetric or gravimetric methods to fill containers with a precise amount of liquid.

- Adjustable Filling Speeds: Liquid filling machines typically have adjustable filling speeds to accommodate different products and production rates.

- Accurate and Repeatable Fill Volumes: Liquid filling machines are designed to dispense consistent, accurate volumes of liquid into containers, with repeatable results.

- Container Compatibility: Liquid filling machines are designed to accommodate a variety of container sizes and shapes, including round, square, oval and flat-sided containers.

- User-friendly Controls: Liquid filling machines often come with user-friendly controls, such as touch screens and intuitive interfaces, to make operation simple and efficient.

- Automatic Container Handling: Liquid filling machines can be equipped with automatic container handling systems to streamline production, including conveyors, bottle unscrambles and orienters.

- Sanitary Design: Liquid filling machines can be designed with sanitary features, such as stainless steel construction, to meet the requirements of food and pharmaceutical applications.

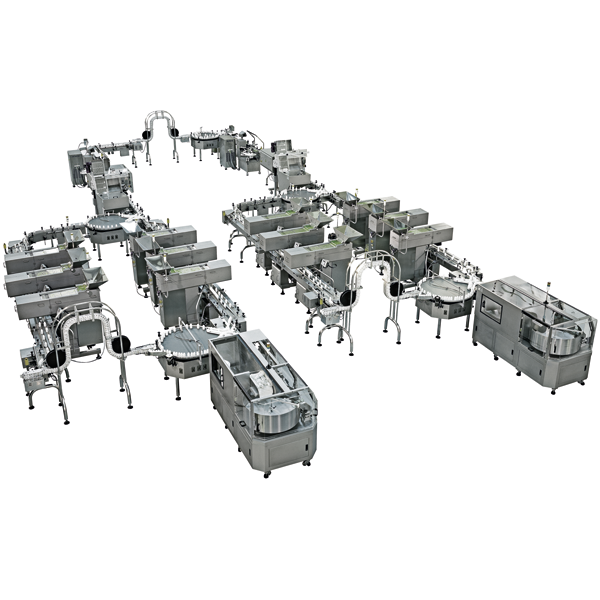

- Integration with Other Equipment: Liquid filling machines can be integrated with other production equipment, such as capping machines and labeling equipment, to form a complete packaging line.

Liquid filling machine manufacturers are proud of their machines because they are adaptable, flexible, and waste-free. The machinery are made to fit the user’s needs and preferences, as well as the form and size of the receptacles they serve. A large industry means higher profits!

Process of Liquid Filling Machine

The inline or horizontal type piston filler is the first step in our bottle liquid filling machine’s procedure. The fluid in the apparatus is directed and measured by this piston filler. After our vial filling machine’s initial procedure of measurement and pouring is complete, the output (liquid) is immediately pumped into a vessel using a stainless filler with one or even more heads. Our liquid filling machine’s process is fast, yet the liquid within the machine is fully safe, and it can be handled without any problems. After the basic process of our bottle filling machine is completed, the secondary phase of the equipment processing begins, and our filling machine can fill a large number of deposits in a minute. Our liquid filling machine also ensures that the entire process runs smoothly without any disruptions. After all of the operations are completed, the finished product (filled bottles, containers, and vials) is collected. As a result, here is the full procedure that describes how our vial filling and packing technology works.