Auto Tablet Film Coating Machine, Sugar Coating Machine

Tablet Coating Machine

The tablet coater equipment is design to create a uniform coating of tablet with an organic solvent, aqueous or enteric coating. It is mainly used in the pharmaceutical industries and the food industries. The equipment conforms to the good manufacturing standards and has a high level of efficiency in operation.

Operation of the Tablet Coating Machine

The application of the coating material is done on a continuously moving bed of tablets. There is a system that also ensures rapid removal of the solvent using a hot air current. Product to be coated are placed in a closed drum, that is in continuous orbital motion , and the coating system sprays the coating material evenly in rotating motion to avoid excess deposit on the tablets.

This tablet coater machine from Bhagwati Pharma Company is designed with energy saving features as well as able to operate hygienically and maintain a clean environment. It is also used in coating of pills and candies in specialized operating processes.

Coat Tablets

- Cover unpleasant taste, color or odor

- Prevent degradation of chemical composition of the tablets. There are certain chemicals that react/degrade on exposure to moisture, ultra-violet light or air.

- For easy identification

- Make blistering easy

- Control drug release, amongst others.

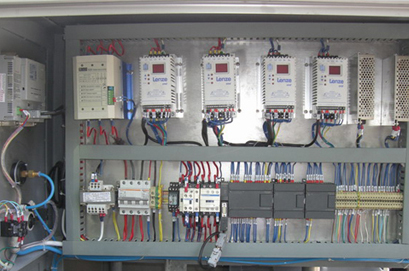

Control System

Touch Screen HMI / PLC BASE Operation Panel

Guide Plate

Peristaltic Pump

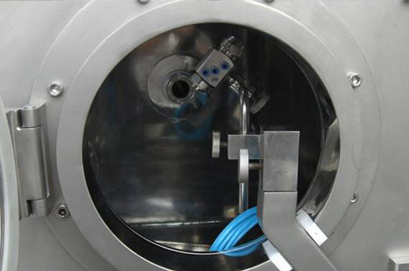

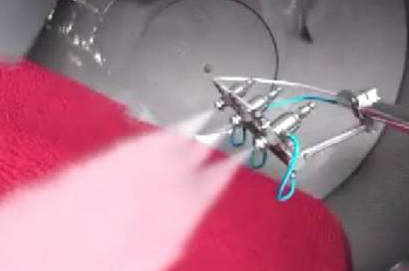

Spraying Gun and nozzle System

Film coating spraying which includes the tank, nozzle and pumps have a simple design.

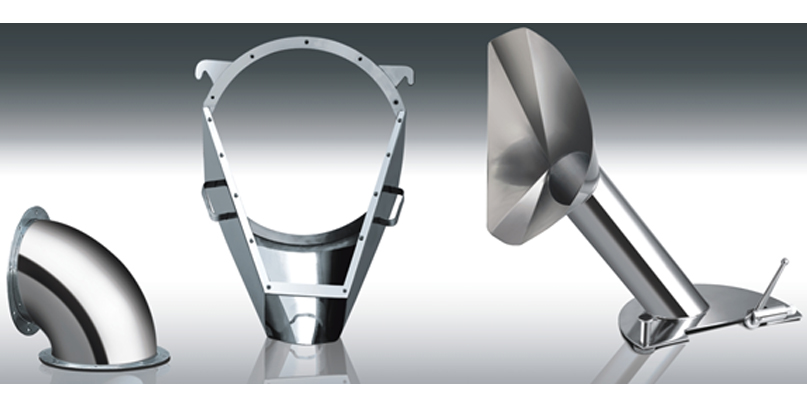

Pan Cooling Surface – Connectors, air pipe and discharging device

- Air distributing device

- Components forming the internal structure of the drum

- Electronic pulse valve

- Air heating unit

- Magnetic stirrer

- Drum filter Movable holder

- Air pipes and fittings

- Exhaust dust collector

- Discharging device

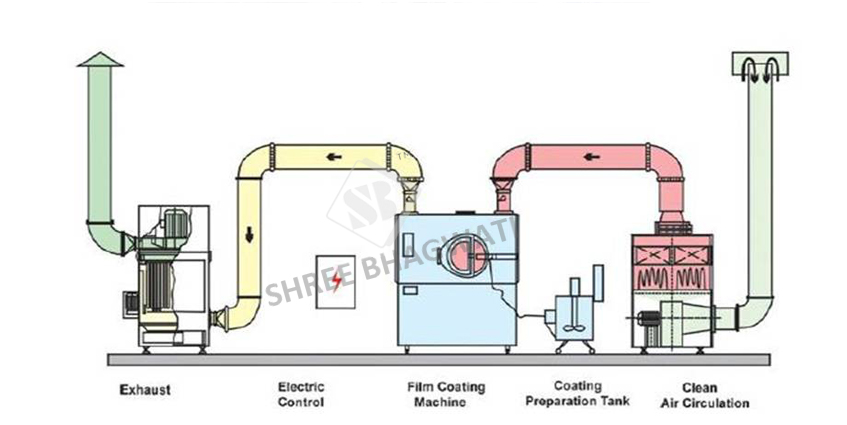

Layout Image below:

| Main Technical Specifications | VGB-40C | VGB-75E | VGB-1S0E | VGB-3S0E | VGB 600E |

|---|---|---|---|---|---|

| Capacity (kg/batch) | 40 | 75 | 150 | 350 | 600 |

| Coating Pan Diameter | 0 850 | 0 950 | 01200 | 01580 | 01580 |

| Coating Pan Depth (mm) | 705 | 780 | 1030 | 1300 | 1900 |

| Coating Pan Opening Diameter (mm) | 0 380 | 0 482 | 0 600 | 0700 | 0850 |

| Coating Pan Rotation (rpm) | 4-23 | 4-23 | 2-15 | 2-11 | 2-10 |

| Motor of Main Machine (kW) | 0.75 | 0.75 | 2.2 | 4 | 5.5 |

| Motor of Hot Air Cabinet (kW) | 1.1 | 1.1 | 1.1 | 2.2 | 5.5 |

| Motor of Exhaust machine (kW) | 3 | 3 | 5.5 | 7.5 | 15 |

| Motor of Peristaltic Pump (kW) | 0.18 | 0.18 | 0.18 | 0.18 | 0.18 |

| Volume of the Solution Tank (L)/max (L) | 40/55 | 40/80 | 60/120 | 100/200 | 220/300 |

| Fan Capacity (m’/hr) | 2000-2500 | 2000-2500 | 2500 – 3000 | 3500/4000 | 3500-5000 |

| Number of Spray Gun | 2 | 2 | 3 | 4 | 6 |

| Dimension of Main Machine (mm) | 1120 x8S0 x 1715 | 1200x965x1750 | 1570 x 1260 x 2000 | 2000 x 1560 x 2300 | 2000×2240 x2320 |

| Dimension of Hot Air Machine (mm) | 1100 x 900 x 2340 | 1100x900x2340 | 1150×1100 x 2510 | 1610 x1085 x 2710 | 1400×1400 x2670 |

| Dimension of Exhaust Machine (mm) | 780 x 720 x 1950 | 780x720x1950 | 915 x 800 x 2030 | 1050 x 1000 x 2100 | 1250×1200 x2200 |

| Main Machine Weight (kg) | 650 | 650 | 750 | 1500 | 2500 |

| Hot Air Machine Weight (kg) | 200 | 200 | 300 | 500 | 800 |

| Exhaust Machine Weight (kg) | 250 | 250 | 400 | 600 | 800 |

| Power of hot air unit electric heating system (Kw) | 20 | 20 | 30 | 50 | 60 |

| Pressure | >0.4Mpa | >0.4Mpa | >0.4Mpa | >0.4Mpa | >0.4Mpa |

| Air Consumption | 80 kg/mi n | 80 kg/min | 100 kg/min | 200 kg/min | 400Kg/h |

Closed drum and allow it to rotate.

Nozzle will begin to spray the tablets with a coating systems. auto process thru PLC systems to controls to all parameter of coating process.

- Film coating

- Sugar coating

- Pellet manufacturing process

Please call us you are to discuss your specific requirements. We will be arrange a trial demonstrating availability our shop floor the high performance of our tablet coating systems.

Tablet Coating Machine Features

Tablet Coating Machine Features Application of Tablet Coater

Application of Tablet Coater