Vibro Sifter (Vibratory Screening Machine, Powder Sieving Machine)

Vibro Sifter Description

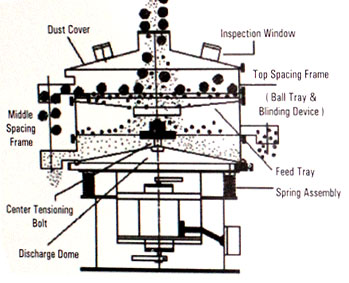

The vibro sifter machine is widely known as Vibro Sifter, Vibro Screen, Vibrating Screen, Lab Vibro Sifter, Pharmaceutical Sifter, Vibro Sieve, Vibro Sifter Machine, and Powder Sieving Machine. Bhagwati Machines India Pvt. Ltd is widely known as a leading manufacturer of high-speed vibro sifter machines. Our offerings include 20” vibro shifter machine, 30” vibro sifter machine, 48” vibro sifter machine and 60” vibro sifter machines for pharmaceutical tablet press. A typical Vibro shifter has a circular gyratory screen which separates mass composition of solids and liquids on the basis of their grades and particle sizes. The vibro sifter machine consists specially designed vibratory motor that generates vibration in three different planes along the vertical axis. This enables us to meet various requirement of our clients global wide.The material is seperated in the vibro screening machine based on the basis of the particle size. It is an essential accessory for the gradation of material in a laboratory. The powder sieving machines are usually available in many different configurations with varying design and capabilities. They have several applications and each one can be custom made for a specific application. It is commonly used in the pharmaceutical and food processing industry.

A Vibratory screening machine is a popular machine in the production of protective screening, monitoring screening as well as grading screening for free flowing, dry or granular bulk material. It has several applications, mainly in the wood processing industry, recycling industry as well as the chemical industry. Additionally, it is also useful for the fertilizer industry, plastic industry, automobile industry, glass industry, ceramic industry and for construction material industry.

The vibro sifter machine works on the principle of gyratory vibrations. The material is separated on the basis of their particle size. Once the motor gets energized, vibration is caused in the screen/sieve making the material to travel across the sieves according to its particle size. To prevent transmission of vibration to the floor, the sieves are suspended on a spring.

We are Designed and manufacturer of Pharmaceutical Vibro Sifters, Vibro Sifter, Vibro Sifter Manufacturer, Vibro Screen, Powder Sieving Machine, Vibrating Sifters with 20″ vibro shifter machine, 30″ vibro sifter machine,36″ vibro sifter , 48″ vibro shifter machine, 60″ vibro sifter machine, 72″ vibro sifter for suitable Food Beverage, FMCG, Pharmaceutical, Ink & Paints, Paper & Pulp, Agriculture Fertilizer.We are Designed and manufacturer of Pharmaceutical Vibro Sifters, Vibro Sifter, Vibro Sifter Manufacturer, Vibro Screen, Powder Sieving Machine, Vibrating Sifters with 20″ vibro shifter machine, 30″ vibro sifter machine,36″ vibro sifter , 48″ vibro shifter machine, 60″ vibro sifter machine, 72″ vibro sifter for suitable Food Beverage, FMCG, Pharmaceutical, Ink & Paints, Paper & Pulp, Agriculture Fertilizer.

| Model | VIBRO SIFTER – SHREE BHAGWATI 20€ | VIBRO SIFTER – SHREE BHAGWATI 30€ | VIBRO SIFTER – SHREE BHAGWATI 36€ | VIBRO SIFTER – SHREE BHAGWATI 48€ | VIBRO SIFTER – SHREE BHAGWATI 60€ | VIBRO SIFTER – SHREE BHAGWATI 72€ |

|---|---|---|---|---|---|---|

| Screen Dia. | 500mm. | 750 mm. | 900 mm. | 1200 mm. | 1500 mm. | 1800 mm. |

| Capacity/Hour * | 25 to 100 Kgs. | 30 to 200 Kgs. | 30 to 300 Kgs. | 50 to 500 Kgs. | 100 to 700 Kgs. | 100 to 1000 Kgs. |

| Charging height | 1200 mm without Lid | 1050 mm without Lid | 1050 mm without Lid | 1050 mm without Lid | 1050 mm without Lid | 1050 mm without Lid |

| Discharging height | 720 mm. | 670 mm. | 670 mm. | 670 mm. | 670 mm. | 670 mm. |

| Main Electric Motor | 0.50 HP/1440 RPM/3 Ph | 1.0 HP/1440 RPM/3 Ph | 1.5 HP/1440 RPM/3 Ph | 1 HP (Heavy Duty) | 2 HP (Heavy Duty) | 3 HP (Heavy Duty) |

Vibro Sifter machine with Single, Double, Triple, Four Deck with Milling – Multi Muill and CO- MILL with Vibro sifter available in 30, 40, 48, 60, 72 inch dia vibratory sieving machine, gyro screen, vibrating screen, vibro sifter machine, sieves, separators and filters with Contact parts in SS 316 , SS 316L, 304 stainless Steel grade can be provided as per user requirement with Interchangeable Screens. Portable, compact and easy to handle and dismantle for cleaning & Flame-proof motor can be supplied as an option for different industry is below :

- PLASTIC & POLYMERS

- AGRICULTURE & FERTILIZER

- PAPER & PULP

- INKS & PAINTS

- PHARMACEUTICAL

- WASTE WATER

- CEMENT & SAND

- GLASS & CERAMICS

- CHEMICAL & PIGMENTS

- MINERAL & METAL

- FMCG – PERSONAL & HOME CARE

- FOOD & BEVERAGE

Note:Specification and features of the machineries are subject to change without any prior notice.

Photos

Video

Specification

Specification Features

Features