Automatic Pre Filled Syringe Filling & Stoppering Machine – PFS-SA-10

Description

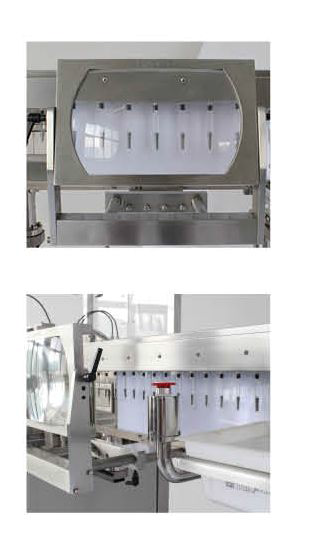

Pre Filled Syringe Filling & Stoppering Machine Model –PFS-SA-10 is very compact and elegant PLC. Based cGMP model for automatic filling and Stoppering operation of pre filled syringe.

We have developed machine model PFS-SA-10 for meeting constantly increasing production requirements of pre-filled syringes. This high-tech filling and stoppering machine for syringes is not only compact and flexible, but also delivers required production speed up to 12000 pieces/hour. Besides, it also offers high precision in dosing operations and a complete protection of syringes.

This modular machine can be equipped with 2 to 5 stoppering/filling stations, hence it is suitable for low speed as well as high speed. Moreover, it is possible to modify these features with further transformations.

As a result of its special design of the work areas, this machine can be easily integrated in different possible layouts. We have given special attention to design moving parts, preferring the usage of linear drive shafts or rotary drive shafts with open wheel to ensure the cleanliness of the machine and for the integration of RABS or isolators.

It offers perfect machine ergonomics and controls arrangement to easily integrate the material dispensing and handling systems in compliance with the directives concerning the assembly of parts in contact with the product.

We offer an advanced machine program for the filing and packaging of sterile liquids and powders. The filling can be in vials, infusion bottles, disposable syringes and carpules. Moreover, the isolators for sterile filling of liquids, powders along with the freeze dry systems to extend the shelf life supports the portfolio.

Functions and feature of Prefilled Syringe Loading Machine & Light Inspection Machine

- Load syringe tubs by hand, automatically den-ester with syringe from the tub,Automatically loading the filled and closed syringes to the machine.

- The filled and closed syringes rotate automatically, the visual inspection is to be Done under a magnifying glass, the unqualified syringes is to be kicked out.

- It can equip with LAF hood.

- This machine can be used as a individual machine, and can also form a multi functional production line. In the production line, before this machine is

- pre-filling syringes filling and capping machine, after this machine is pre-filling syringe rod screwing labeling machine.

Application : Visual inspection of ampoules, vials, pre-filled syringes, infusion bottles, etc.

Main technical parameter

| Syringe volume | 0.5-50ml |

| Magnification | 2.5X |

| Speed | 1200-3600(pcs/hour) |

| Total power | 1.0Kw |

| Compressed air | 0.55-0.75 Mpa 20L/S |

Note: Laminar flow is required 1. 5 Meters. X 1. 0 meter. For filling and Stoppering M/C.

A company producing a lyophilized product packaged with reconstitution fluid for intramuscular injection considers marketing a prefilled syringe for the same indication, in the management of rheumatoid arthritis. The company must reformulate the molecule to a stable liquid. The route of administration will remain the same.

The container–closure device, however, will change, which means that some materials and the functionality of the system will be different. In addition, long-term storage conditions may change because of the new formulation.

Operation

Operation Specification

Specification Features

Features Utility

Utility Important Requirements.

Important Requirements.