Packaging and Processing Machinery Manufacturer – Collaboration, Joint venture partner in INDIA

Formed in 1996 with various milestones in-terms of Technology-Tie-ups gives a complete process solution from start to end with four manufacturing Facilities in India

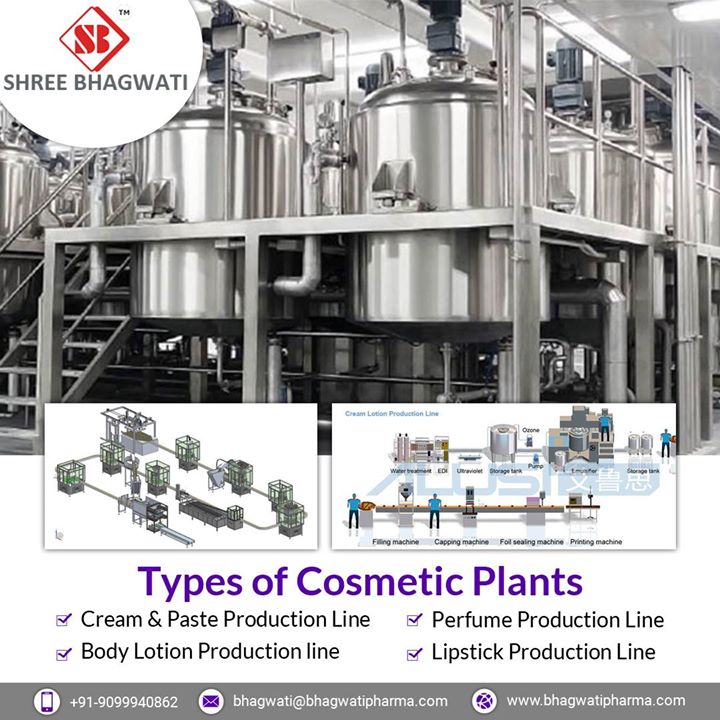

This is a Joint Venture Handles mainly Granulation Process Equipments and entails the manufacture and supply of High Shear Mixer Granulators Fluid Bed Drier & Processor, Ploughshare Mixer, Automatic coating mahine, Continuous Granulations, Blenders, Vaccum & Hot Tray Driers, Rotocone Dryer , Sifters, Mills and botte Packaging line machinries etc.. under Technology transfer from , USA , Germany & Italy. Critical components are imported from parent company to ensure performance matches with Europe made machine. German team in India ensures quality and performance meet German standards. This unit also caters to Cosmetics, Chemicals, Fine Chemicals and other allied Industries other than the Pharmaceutical Industry. (This factory – UNIT – 3 is in Ankleshwar)

Shree Bhagwati Machtech all patner with Joint Venture all committed to meet the expectation of the customer and become a reliable and preferred partners for its products and services.

There has been a sharp increase in industries and manufacturing units of food, drugs, and other materials. It is for this reason, packaging and processing machinery manufacturers have been looking for partners to collaborate and for more joint ventures. When it comes to increasing business through partnership, India leads in many ways.

Why India for packaging and processing machinery collaboration

The ‘Make in India’ drive has attracted business persons from all across the world. The government has loosened certain rules and regulations for FDI i.e. foreign direct investments. After China, India is the country that most of the MNCs is looking for.

Especially pharmaceutical companies are aiming to establish their manufacturing units in India for more tax benefits and exporting. The best part of having such collaboration and joint venture partner in India for packaging and processing machinery manufacturers is that India itself is the best consumer due to its huge population.

Applications of packaging and processing

India is the biggest machinery production country for packaging and processing. There are many sectors where packaging and processing happen; however, here are a few sectors where such machines are widely used –

- Pharmaceuticals

- Nutraceuticals

- Biotech

- Foods, bakery, and dairy

- Cosmetics

- Confectionary

- Agriculture, agro-chemical

- Chemicals and paints

- Herbaceuticals

Apart from tax benefits and other favors, India has potential manpower that is available at quite affordable prices as compared to the first world countries like the US and UK. India has been the greatest interest for other countries to import packaging and processing machines. Here are the major countries or regions that have potential business deals with India –

- The United States

- The United Kingdom

- Australia

- African continent

- Oceania region

- Europe especially Germany and Italy

- Middle East countries

The above-mentioned countries deal with importing advanced machines and equipment for packaging and processing. That said, robotics into pharma packaging has been on the rage these days. There are many leading players in the industry in India who meet demand and supply with their great production capacity.

Rise in global pharmaceutical productions

Global pharmaceutical processing and packaging equipment market is expected to touch at a CAGR of approximately 3.9% during the tenure to climb over USD 20 billion in the next five years as compared to nearly USD 17 billion from the last year.

With immense requirements in developing newer drugs through researchers, the growth in generic drug manufacturing and high-potency medicines is quite evitable. To cater this great demand, more and more manufacturing of packaging and processing machinery manufacturers are diving into national and international markets.

Machines are now manufactured according to the requirements of the production units. The large equipment is now tailored or specially engineered as per the order. As mentioned above, due to affordable labor costs, relaxation in industry norms and laws, and lands at cheaper prices are the unique selling points of India. It is for this reason, investors from the first world countries are now opting for India to either shift or start their own manufacturing units for packaging and processing machinery for pharmaceuticals and other industries.