Sauce, Ketchup Glass Bottle filling and Packing Machine – Viscous line

Introduction– The experts for packaging machines manufacture them with great flexibility and customization to meet the varied and demanding requirements for use in sauce and ketchup bottle filling applications. Due to the high quality and operating life, these machines have achieved worldwide recognition. Investing in an automatic filling line can be useful in achieving improved levels of precision and lesser opportunity of operator errors. A variety of filling techniques are implemented in the sauces and dressing sector like the volumetric methodology, mass, and weight flow filling technology, and the heated or room temperature filling. A filling and packing line should ensure an environment meeting hygiene standards and a great deal of flexibility like quick tool changeovers.

Advantages of investing in a Ketchup/ Glass Bottle filling and packing machine

Alimentary products must be filled and packed with special care complying with all hygiene requirements. Manufacturers of the present-day offer a wide variety of liquid filling equipment, cappers, labelers, and conveyors that can fill and package sauce along with many other types of thicker and viscous sauces. This equipment can provide-

- The best dependability of fill

- Economical in terms of large volumes manufactured

- Less product waste especially if the line of product is expensive

- Enhanced speeds and efficacy

- Versatility as sauces differ in thickness owing to the ingredients present in them

- Quick tool changeovers for a greater flexibility

- Packaging to ensure the protection of the sauce from leakage and shielding them against any kind of contaminant. This is especially useful when the product needs to be transported long-distance or exported.

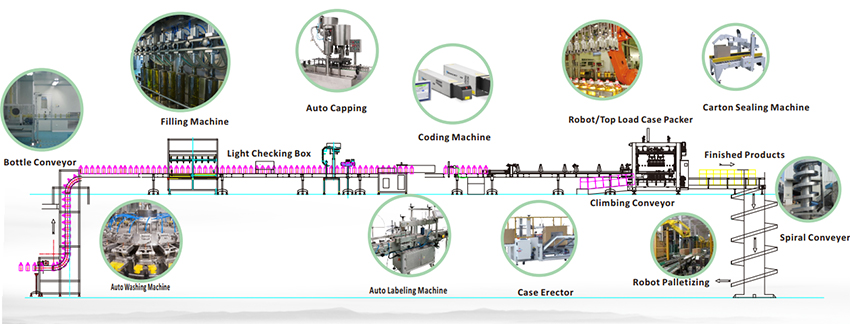

Working of the Sauce bottle filling machine

The sauce bottle filling machine is equipped with a horizontal mixing hopper that ensures the liquid is uniform in the filling process and no stratification occurs while achieving the filling accuracy of each bottle. The automatic sauce filling machine is designed to shorten the distance that is present between the lower hopper and the filling head. This helps to overcome the uneven filling of materials in the filling process. There is an option of customization of filling heads in this automatic filling machine according to client specifications. Following the liquid filling process, the capping and sealing machines fit onto bottles and jars of various shapes and sizes.

The capping and sealing machine offer an air-tight seal and prevent any adulteration of the sauces. A well-defined system of conveyors carries the product through the filling and packaging processes. Subsequently, customized labels are attached in a customized way to promote the information and branding process. Intelligent and information systems are added into the control panel as the sauce filling process requires filling liquid with high concentration, no leakage, and in a clean and tidy environment. Fast and accurate filling and packing machines integrated with advanced communication provide an opportunity to increase the output and efficiency of production.

Bottom Line– The sauce or ketchup filling and packaging equipment gives its clients the complete ability to customize the production lines for sauces and allied viscosity products. There is a filling rotary valve, the material of which can be designed as per the specification and need of the product. The comprehensive setup of reliable sauce filling products can result in an efficient production line that can give consistent results for years. The equipment is made of quality components that are corrosion resistant and the piston pumps fill all the bottles with high filling speed and filling precision.