Tube Filling Machine, Tube Filler

Description

SHREE BHAGWATI tube fillers Sealer machine fill products in cylindrical metal / laminate / plastic tubes and close tubes. tube filler machine capacities ranging from 35 to 150 tubes / minute are available with different model like Linear tube filling machine , rotary tube filling machine to meet today’s tube packaging demands in different industry. our tube filler machine can filling viscous and semi-viscous products are handled, like Gel, shampoo, ointment, cosmetics, toothpaste, cream/gel, adhesive, chocolate, sealant, mayonnaise and many more.

New model tube filler machines have been ergonomically special designed to ensure that smooth user friendly working areas are easily accessible for setting, changeover and maintenance. On the other hand, for linear-chain tube fillers might appear longer but are still designed with sleekness in mind.

Many our tube filler machine model including laminated tube filling machine,cosmetic tube filling machine,plastic tube filler,semi-automatic tube filler,automatic tube filling machine,rotary tube filling machine,linear tube filling machine,high speed tube filling machine,tooth paste tube filling machine,filling machines for plastic tube,lotion tube filling machine,pharmaceutical tube filling machine,medicine tube filling machine,cosmetic cream tube filling machine,ointment tube filling machine

Basis of Design

The Tube Filling Machine shall be used for filling and sealing of tubes such as laminate tubes, aluminium and plastic tubes for semi-solid products.

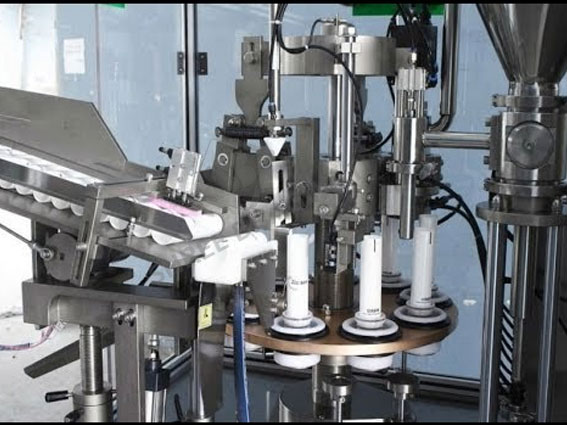

The Tube Filling Machine shall automatically operate to fill laminate tubes, aluminium tubes or plastic tubes with semi-solid products (Semi-solid products such as cream, gel, and ointment.) and seal the bottom of the tube with filled products with heat sealer or crimper. The tubes are manually fed to the tube feeder. A tube will be transferred via a single transfer chute and turned the bottom up. The tube is moved by rotation wheel to the dosing station. Semi-solid product prepared in the semi-solid manufacturing suite shall be transferred via a mobile vessel or vat and connected to the filling machine. Semi-solid products shall be supplied to the filling machine nozzle by vacuum or sanitary pump, as per the filling machine packaged skid design. The tube is filled with product with adjustable volume. Then the filled tube is moved to the seal station to seal the bottom of the tube whether heat sealer or laminate crimper. The sealed tube is conveyed out of the machine on the downstream by the transport system.

Capacity

The Tube Filling Machine shall be capable of operating the following filling weight and speeds Available : 30 tube fill per minute , 40 tube per minute , 60 tube per minute , 150 tube per minute with different model

| Fill Volume | 2 gm to 300 gm |

|---|---|

| Model | Rotary and Linear both model |

Critical Quality Attributes (CQA)

The Tube Filling Machine shall operate in accordance with the following system specific Critical Quality Attributes:

| Attribute | Acceptance Criteria |

|---|---|

| Fill mass | ± 0.5% |

Critical Process Parameters (CPP)

All CPPs shall be configurable in the system. To avoid repeating data, parameter values may be referred to in this document by enclosing the parameter name in braces, such as {Conductivity}.

Initial and default CPP values are provided in the table below:

The system shall provide continuous monitoring with digital display, audible alarms and alarm messages on HMI for the following:

| Parameter | Value |

|---|---|

| Tube filling speed | Up to 4,800 tubes/hr – depend of fill volume |

| Air blow pressure at cleaning nozzle | Filter Air – customer scope |

| Temperature of hot air and hot jaws at thermos sealing |

Imported German Make Hot air systems fitted with machine

|

| Hot air pressure at thermos sealing |

Mechanical with special designed attachment

|

| Temperature at hopper | Optional Provide – Jacketed Hopper with temperature controller |

Tube Feeder

- The tube filling machine shall be designed to allow manual loading of tubes ergonomically into the magazine with automatic tube feeding into the dosing station.

- The tube shall be orderly fed to the dosing station and placed in vertical position on dedicated position. The open bottom side of the tube is up.

Dosing Station

- The tube shall be internally cleaned by adjustable air blow and dust aspiration device by vacuum.

- A terminal filter shall be used for the compressed air to the cleaning station.

- Semi-solid product shall be supplied from a mobile vessel or vat to the heated hopper by using vacuum or sanitary pump integral with the filling machine with minimum quantity of product remaining inside the vessel a the completion of filling.

- The heated hopper with scraper shall be used to keep homogeneity and consistent temperature of the product.

- Adjuster shall be used for the central dosing volume adjustment. The dosing volume as well as the dosing speed shall be adjusted at the operating terminal.

- The dosing station shall automatically detect and alert the operator if any dosing station is missing a tube.

Sealing Station

- Plastic tube shall be completely sealed by thermos sealing equipped with high frequency hot jaws and hot air. Possibility to customize designer seals.

- Laminate tube and Aluminium tube shall be sealed by tube closing unit for normal, double, or saddle fold.

- Coding on the outer of the tube shall be able to do in this station.

Operation

Operation Specification

Specification Application

Application Utility

Utility