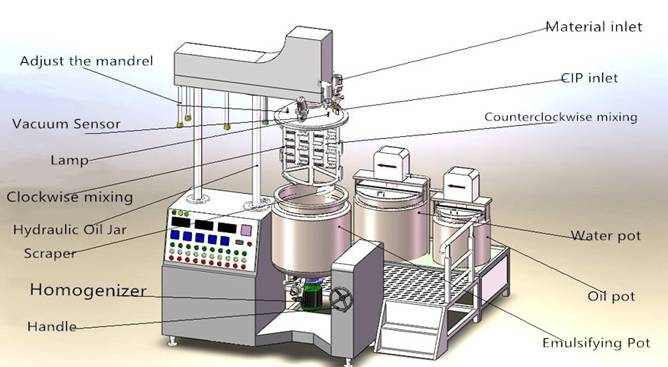

Vacuum Emulsifying Mixer, Cream Mixer

A Vacuum Emulsifying Mixer is generally used for mixing of high viscosity material for emulsification. The cream mixer, as the name suggests, is used to manufacture cream, ointment, lotion in various industries. These industries include- cosmetic, pharmaceutical, food and chemical. The vacuum emulsifying mixer makes use of steam heating or electric heating. For cooling, it utilizes tap water or chilled water. The machine contact parts are made of stainless steel which imparts durability to the machine giving it a long life. The batch size of cream mixers varies, ranging from 30 LTR to 2000 LTR.

Vacuum Emulsifying Mixer, Cream Mixer

- Mixer Batch size: 30, 50,100, 200, 300, 500, 1000, 2000 LTR

- Contact parts: Stainless steel 316 or SS 316 L

- Maintain: top entry homogenizer and anchor agitator with scrapers with Dish head top and bottom, double

jacketed. - Lifting system: hydraulic or NA

- Vacuum pump: Nash-elmo pump or Pump made in Shanghai

- Heating/Cooling system: Steam heating or electric heating/ tap-water cooling or together with chilled water

cooling. - Dissolving tanks: Dish head bottom and open flat top (dish head top optional), double jacketed.

- Control system: Buttons with instruments or PLC controlled with HMI.

Photos

Videos

Specifications and Descriptions

Specifications and Descriptions